Balanced flat metal conveyor belt - Predominant Choice in Food Industrial

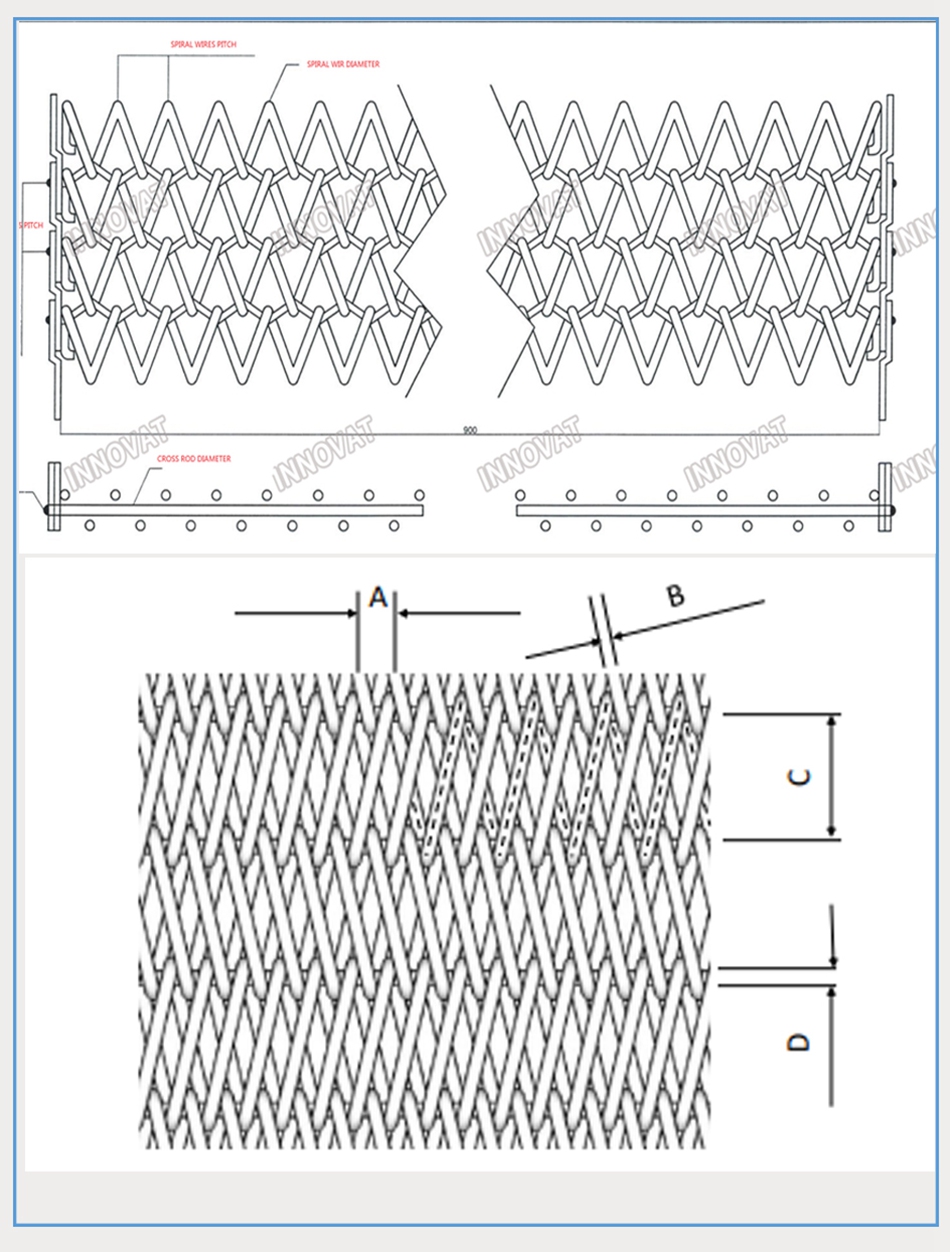

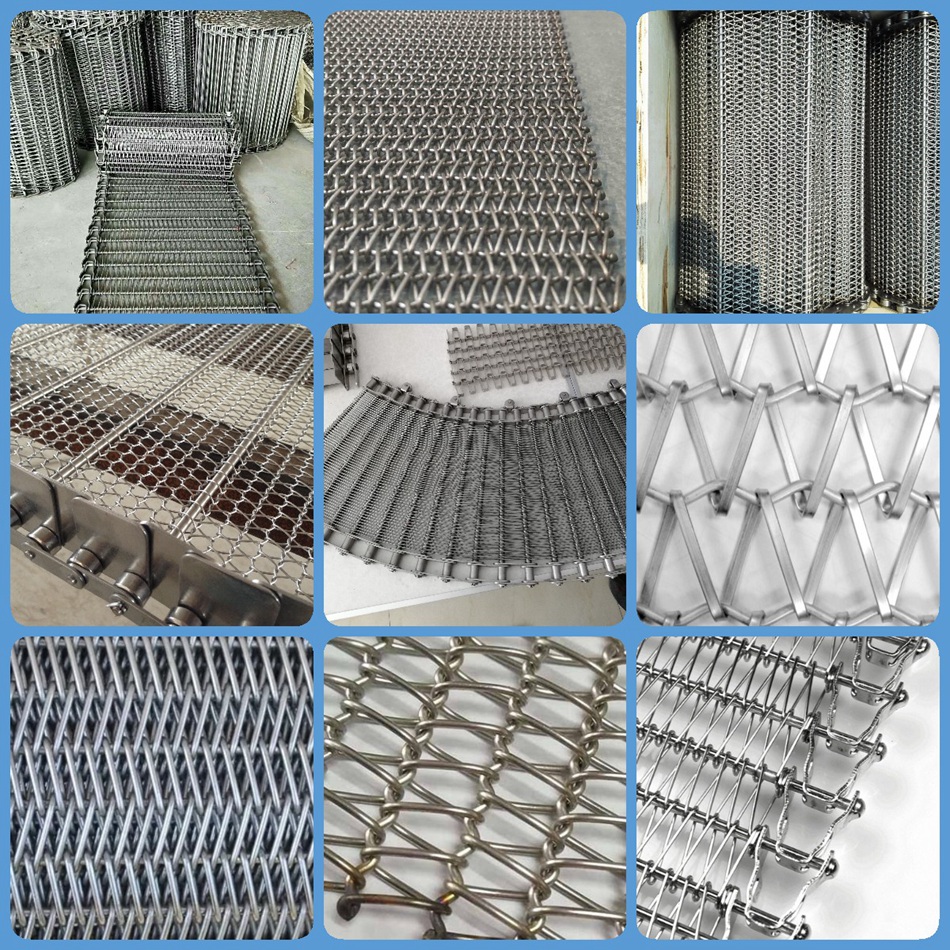

Balanced flat metal conveyor belt, also known as wide spiral link belts, are constructed of round or flat spiral wires joined by crimped rods. Driven, tensioned and guided by a sprocket or a plain roller, balanced flat metal conveyor belt is an economical choice to provide smooth and stable movement for medium load applications and various others as shown below:

Food processing industrial such as draining, cooling, baking and washing, etc.

Balanced Flat Metal Conveyor Belt - Predominant Choice in Food Industrial

Balanced flat metal conveyor belt, also known as wide spiral link belts, are constructed of round or flat spiral wires joined by crimped rods. Driven, tensioned and guided by a sprocket or a plain roller, balanced flat metal conveyor belt is an economical choice to provide smooth and stable movement for medium load applications and various others as shown below:

Food processing industrial such as draining, cooling, baking and washing, etc.

Glass and ceramic industry.

Metalworking and hardening.

Chemical industry such as conveying rubber and plastic products.

Serving as screen, guard and mesh panels.

Decoration.

Acting as heat treatment belt or pasteurizing belt, etc.

| Material | carbon steel, SS 201, SS 304, SS 316, SS 314. |

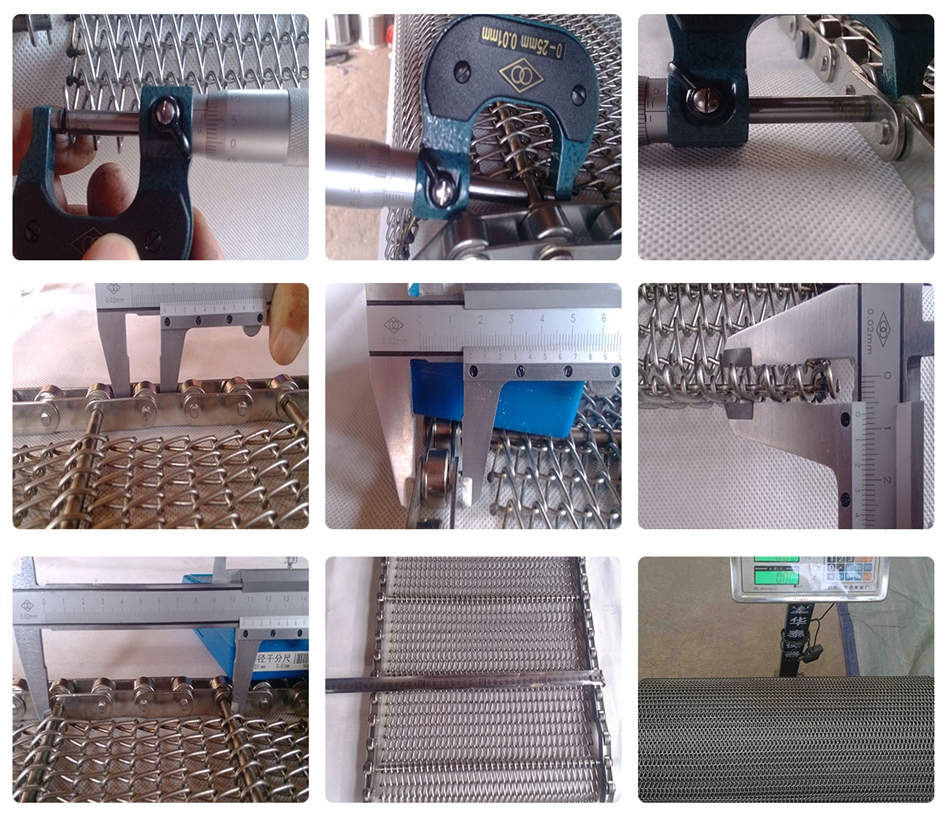

| Round wire diameter | 1.2 mm, 1.4 mm, 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm |

| Flat wire size | from 1.0 mm × 0.7 mm to 6.0 mm × 3.0 mm |

| Cross rod diameter | 0.8 mm to 8.0 mm |

| Pitch of spirals | 2.8mm to 40mm |

| Belt width | 200 mm to 5,000 mm |

| Cross bar pitch | 5 mm to 50.8 mm |

| Belt speed | 0.5 m/min to 60 m/min |

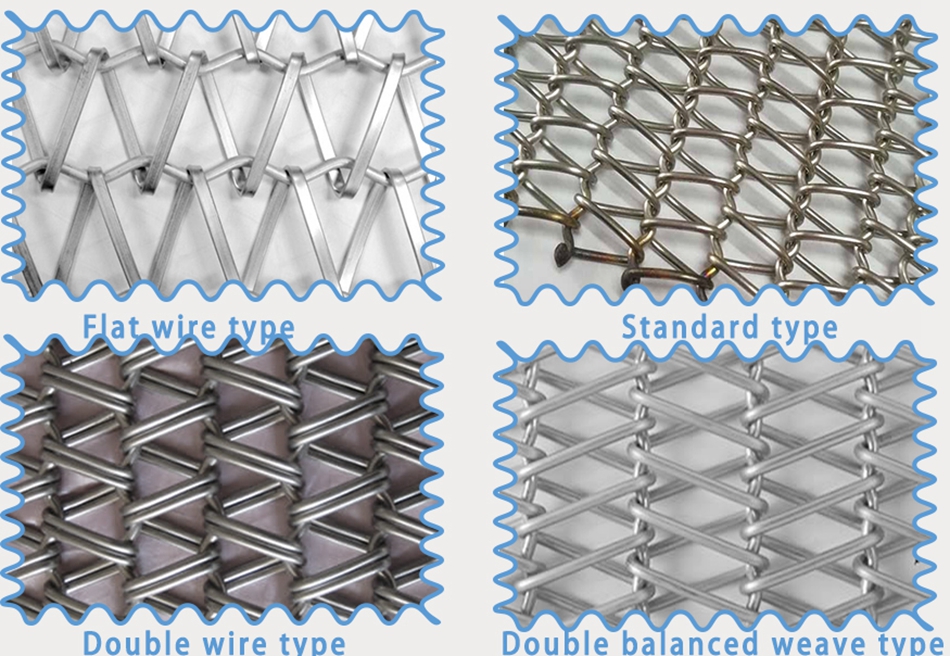

| Type | flat wire type, standard type, double wire type and double balanced weave type |

| Type | Spiral wire pitch | Cross rod pitch | Spiral wire diameter | Cross wire diameter |

| BWCB-1 | 4mm | 4mm | 0.9mm to 1.2mm | 1.2mm to 1.6mm |

| BWCB-2 | 5mm | 6.4mm | 0.9mm to 1.2mm | 1.2mm to 1.6mm |

| BWCB-3 | 5mm | 5mm | 0.9mm to 1.6mm | 1.2mm to 1.6mm |

| BWCB-4 | 6mm | 6mm | 0.9mm to 1.6mm | 1.2mm to 1.6mm |

| BWCB-5 | 6mm | 8mm | 0.9mm to 1.2mm | 1.2mm to 1.6mm |

| BWCB-6 | 6mm | 10mm | 0.9mm to 1.6mm | 1.2mm to 1.6mm |

| BWCB-7 | 8mm | 12mm | 1.2mm to 2.0mm | 1.2mm to 2.5mm |

| BWCB-8 | 8mm | 13mm | 1.2mm to 2.0mm | 1.2mm to 2.5mm |

| BWCB-9 | 8mm | 15mm | 1.2mm to 2.0mm | 1.2mm to 2.5mm |

| BWCB-10 | 11mm | 15mm | 1.2mm to 2.0mm | 1.2mm to 2.5mm |

| BWCB-11 | 11mm | 20mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-12 | 11mm | 25mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-13 | 11mm | 27mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-14 | 15mm | 20mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-15 | 15mm | 25mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-16 | 22mm | 23mm | 1.6mm to 3.0mm | 1.6mm to 3.0mm |

| BWCB-17 | 22mm | 33mm | 1.6mm to 3.0mm | 2.0mm to 4.0mm |

No need for extra wire to stretch or bend

Offers a variety of edge finishing options

Requires less energy to operate

Exclusive proprietary pretreatment process extends belt life in carbon-rich environments

Quality cross rods with larger diameter than spiral wires for higher durability.

Temperature range: -50°C to 1100°C.

Quick and easy to install.

Simple maintenance by replacing the broken parts easily.

Resistant to acid, alkaline, chemical, abrasion and corrosion.

Complying with food safety standards such as FDA, GMP and others up your request.

Edge Availability

Welded Edge (W) – mesh only

Welded Edge (W) – mesh only

This is the most common and economical edge finish. With welding together of both the coil and crimp wires there are not cut wire ends.

Laddered Edge (LD) – mesh only

Laddered Edge (LD) – mesh only

Laddered edge is often used where welds are not desirable for the application. It is also an option in applications where welding facilities are not available. Generally this edge finish is only available for meshes with a relatively large crimp wire pitch down the length.

Hook Edge (U) – mesh only

Hook Edge (U) – mesh only

It is also an option in applications where welding facilities are not available. The belt edge is also smooth and allows more belt edge flexibility. Generally this edge finish is only available for meshes with a relatively large crimp wire pitch down the length.

Chain Edge Driven Mesh

With welded washer

With welded washer

This is the most common and economical style of finish to a chain edge belt and comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. The cross rods are finished at the outside chain edges with a welded washer

With Cotter Pin & Washer

With Cotter Pin & Washer

Although less economical this type of assembly allows the customer or service personnel the ability to replace the edge drive chains when the mesh and rods are still serviceable. The assembly comprises of a central mesh carried through the system by means of edge chains with carrier cross rods through both mesh and edge chains. The cross rods are finished at the outside with a drilled hole to allow the fitment of a washer & cotter pin. It also allows the repair replacement of sections of belt without the need to grind off rod heads and weld back together.

Drawing

Type

Inspection

Show

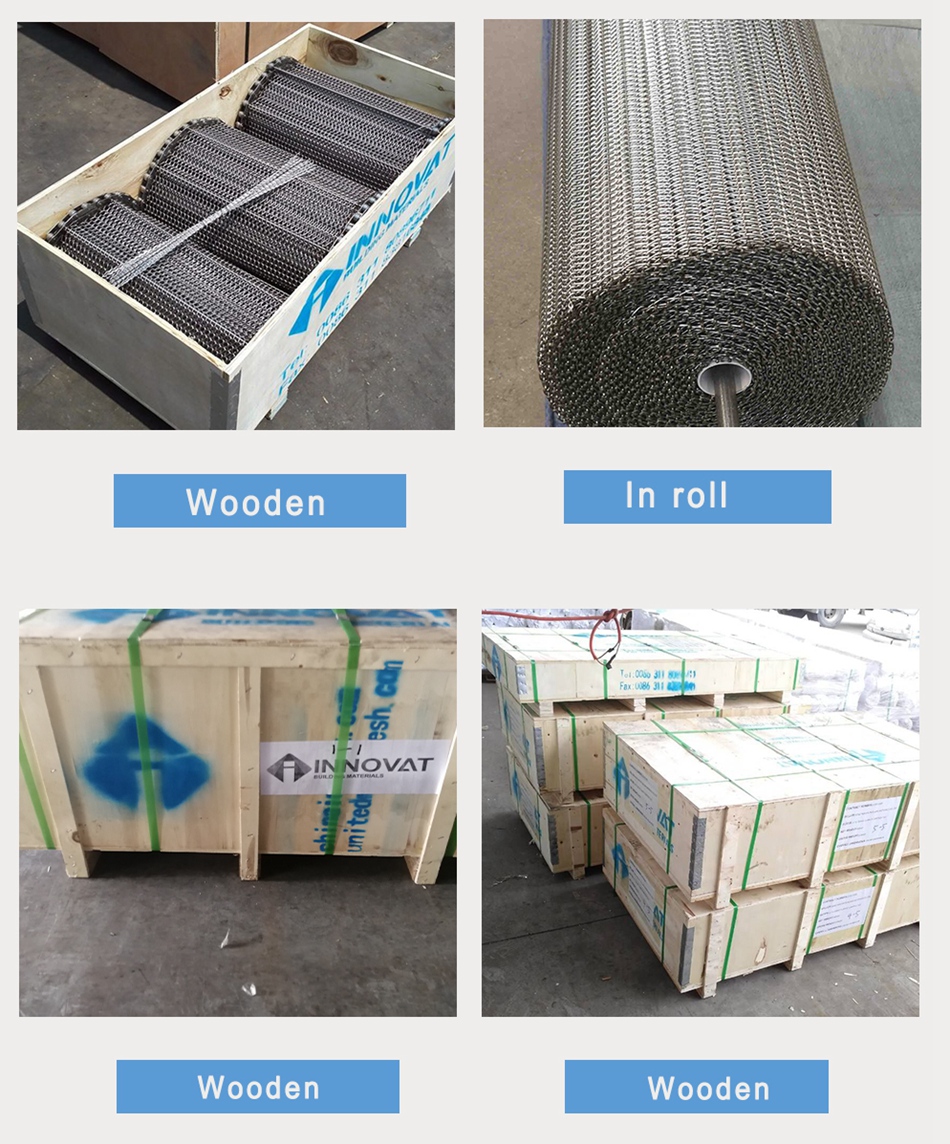

Packing

Application