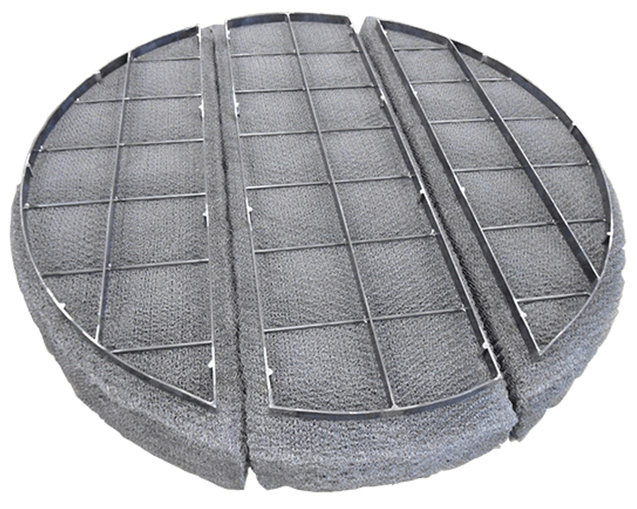

Mesh demister, also called gas liquid separator or mist eliminator or Corrugated Packing Demister Pad, is a specially designed device to separate liquid droplet from vapour steams. It is mainly used to separate liquid droplets with diameter of 3μm-5μm and larger in separation towers.

A wire mesh demister, also known as a mist eliminator or a mesh pad, is a specialized device used in various industrial processes to separate and remove liquid droplets or mist from gas streams. It consists of a mesh pad made from woven or knitted wire that allows gas to pass through while capturing and coalescing small liquid particles.

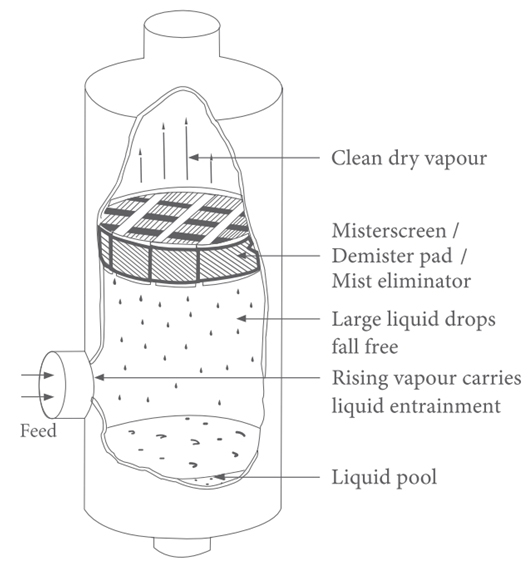

When the gas with mist rises and passes through the wire mesh at a constant speed, the rising mist will collide with the mesh filament due to inertia and attach to the surface filament. The mist will spread on the surface of the filament and the liquid droplets will advance along the filament at the intersection of the two wires. The droplets gradually grow and separate from the filament until the force of gravity of the droplets exceeds the upward force of the gas and the surface tension of the liquid, while almost no gas passes through the demisting pad.

Separation of gases from the droplets improves operating conditions, optimizes process indicators, reduces equipment corrosion, extends equipment life, increases the amount of valuable material handled and recycled, protects the environment, and reduces air pollution.

Simple structure.

Light weight and easy to transport.

High porosity, small pressure drop.

Large specific surface area, high separation efficiency.

Easy to install, operate and maintain.

Durable and long service life.

Corrosion and rust resistant.

Mesh demister efficiency is preliminary a function of droplets size, wire size, specific surface area of the mesh, pad thickness and physical properties of the system. For a standard specification mesh demister ( wire ø 0.28 mm, density 145 kg/m³, surface area 300 m²/m³ ) removal efficiency is typically 100 % for a droplets 5 μm and greater in diameter. Higher surface area mesh demister 500 m²/ m³ using a reduce wire diameter 0.15mm can be used to improve the removal efficiency.

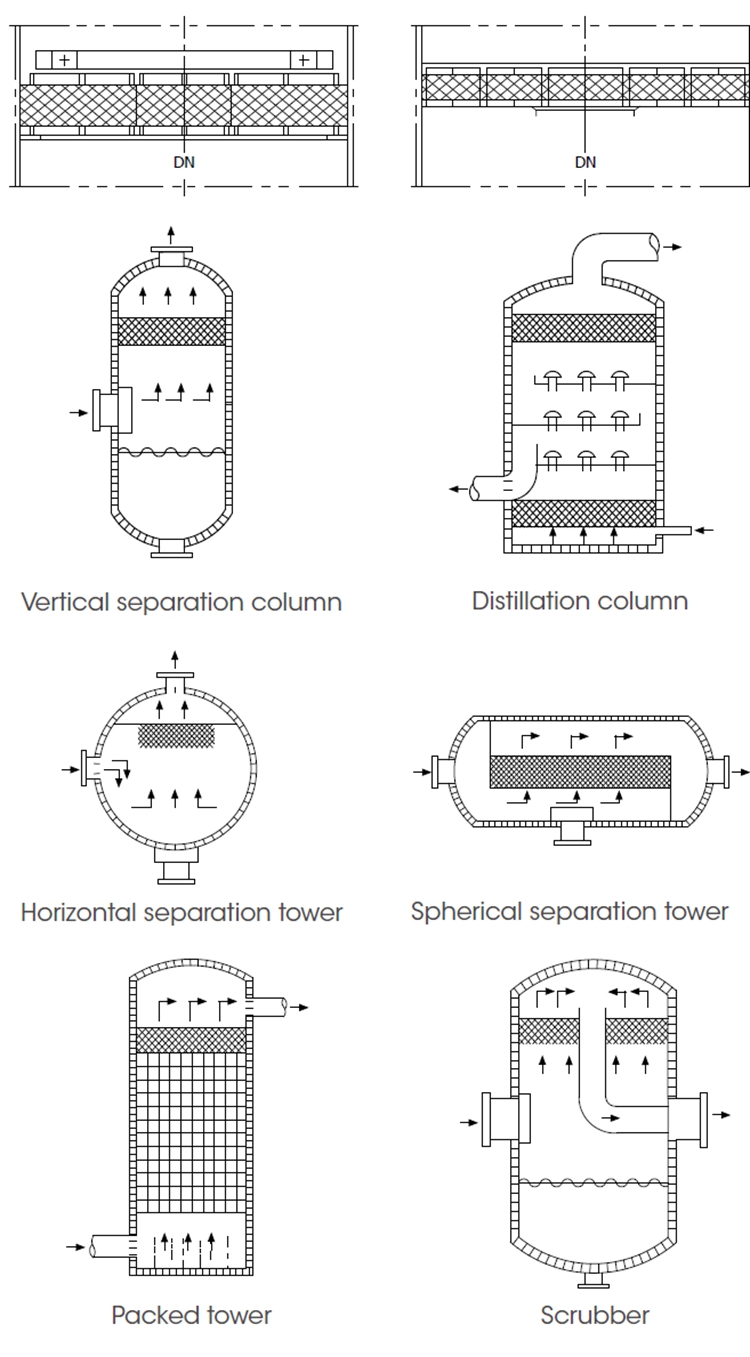

Mesh demister can be installing either horizontally or vertically. With horizontal gas flow through the demister the capacity is 305 greater than compared to vertical flow, thus the demister can be smaller.

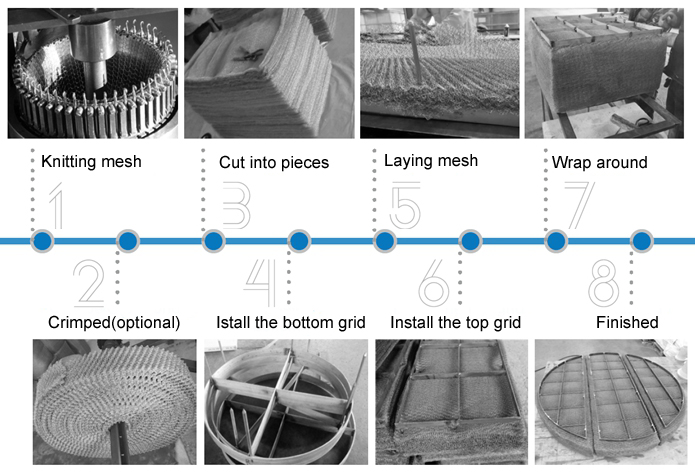

Mesh pads are typically 150mm thick with 25mm thick grids on either side making on overall thickness of 200mm. Many years of experience have shown that a 150 mm pad thickness provide optimum performance in hydrocarbon process with a vertical gas flow configuration.

| Item | Density(kg/m3) | Free Volume(%) | Surface area(m2/m3) | Domestic Model | Other Companies Model | |||||||

| Metex | York | Becoil | Knitmesh | Vico-tex | Uop | Koch | Acs | |||||

| 1 | 80 | 99.0 | 158 | H | Hi-Thtuput | 931 | 954 | 4536 | 160 | B | 511 | 7CA |

| 2 | 120 | 98.5 | 210 | L | 422 | |||||||

| 3 | 144 | 98.2 | 280 | N | Nu-Standard | 431 | 9030 | 280 | A | 911 | 4CA | |

| 4 | 128 | 98.4 | 460 | SN | 326 | 415 | 706 | |||||

| 5 | 193 | 97.5 | 375 | SL | Xtra-Dense | 421 | 890 | 9033 | 380 | C | 1211 | 4BA |

| 6 | 300 | 96.2 | 575 | SM | ||||||||

| 7 | 390 | 95.0 | 750 | SH | ||||||||

| 8 | 220 | 97.2 | 905 | T | ||||||||

| 9 | 432 | 94.5 | 1780 | R | Multi-Strand | 333 | 800 | |||||

| 10 | 220 | 97.2 | 428 | W | Wound | |||||||

| 11 | 160 | 96.7 | 5000 | GS | 371 | |||||||

| Density 80 is suitable for both metal materials and plastic materialsOther models in only suitable for metal materialsWe can provide available in virtually any size or shape, individual styles of PP demister can be supplied to meet specific customer needs. | ||||||||||||

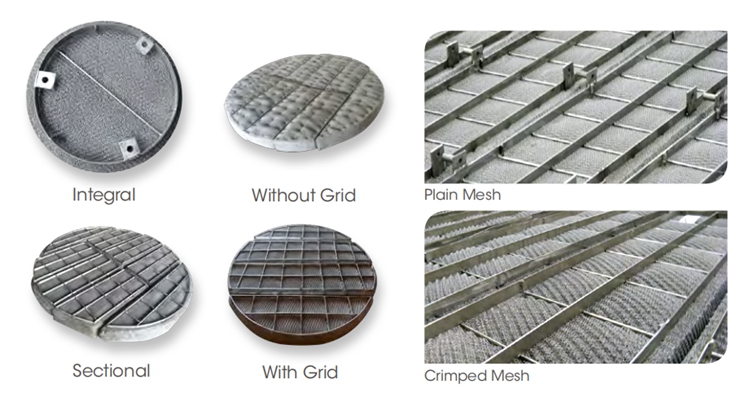

If the diameter is larger than 500 mm. It will be split into sections in the range of 300 mm to 400 mm

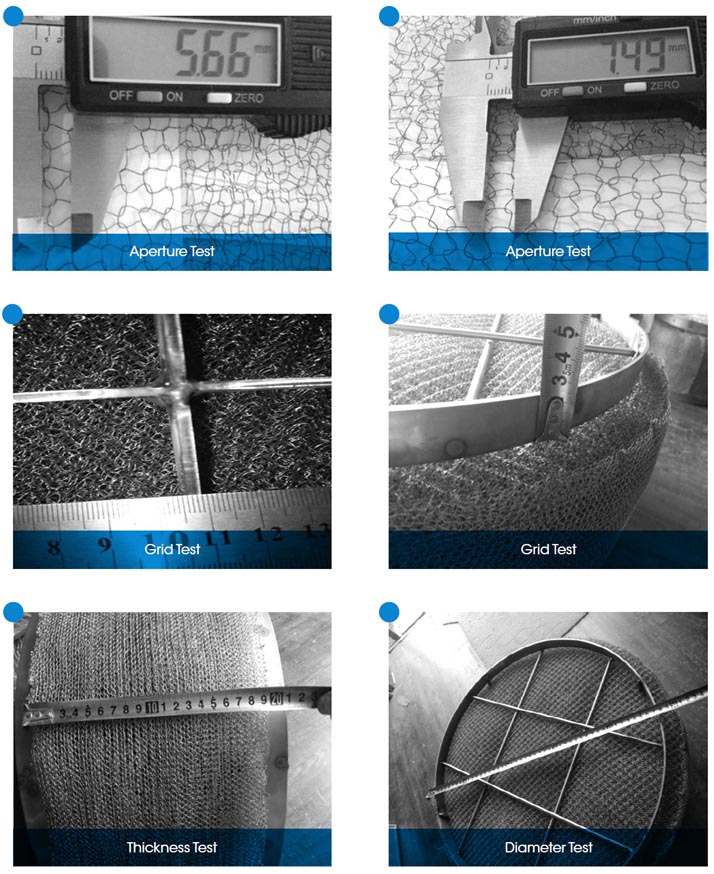

Product Quality Inspection

According to different using condition, it can be divided into upload type and download types

● Upload type. When the opening is located in the above of the demister pad or when there's flange above the demister pad, you should choose the upload demister pad. Diameter of

upload type is ranges from 300 mm to 5200 mm.

● Download type. When the opening is in the below of the demister pad, you should choose the download type demister pad. Diameter of upload type is ranges from 700 mm to 4600 mm.

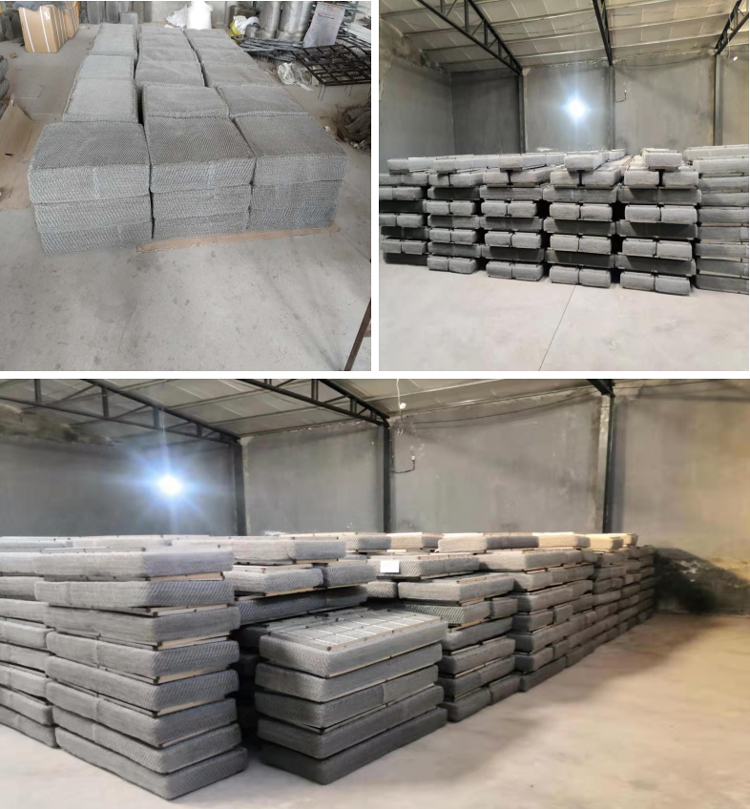

Product Stocks

Product Packages

The standard package of demister pad is wooden case, other package can be customized according to customer’s requirements.

Tower internals

In the desulfurization Tower, fractionating column, absorbing capacity Tower and other chemical equipment as tower internals for mist

or dust separation, to achieve air purification,Flue Gas Desulfurization, Water deputation and other purposes.

Chemical industry

In the chemical industry, it is made into a screen demister, screen mist remover, which will eliminate or capture the droplets and droplets

entrained in the gas during catalyst and distillation, evaporation, absorption and other processes.

Other Industry

It is used for physical or mechanical separation of crude oil dehydration, crude oil gas freeing and gas-liquid separation in the process of petroleum smelting;

Separation and filtration devices in the process of light industry manufacturing; And even widely used in the fields of medicine, aerospace, machinery, etc.