Perforated steel tubing is a type of steel pipe that has holes or perforations evenly distributed along its length. These holes can serve various purposes depending on how the tubing will be used. The process of creating these holes involves techniques like punching, drilling, or laser cutting. This type of tubing finds applications in industries such as construction, automotive, architecture, and more. The holes can serve functions such as filtration, noise reduction, heat dissipation, structural support, and aesthetic design. The choice of materials, coatings, hole sizes, and patterns can be tailored to the specific needs of the project or application.

Perforated steel tubing is a type of steel pipe that has holes or perforations evenly distributed along its length. These holes can serve various purposes depending on how the tubing will be used. The process of creating these holes involves techniques like punching, drilling, or laser cutting. This type of tubing finds applications in industries such as construction, automotive, architecture, and more. The holes can serve functions such as filtration, noise reduction, heat dissipation, structural support, and aesthetic design. The choice of materials, coatings, hole sizes, and patterns can be tailored to the specific needs of the project or application.

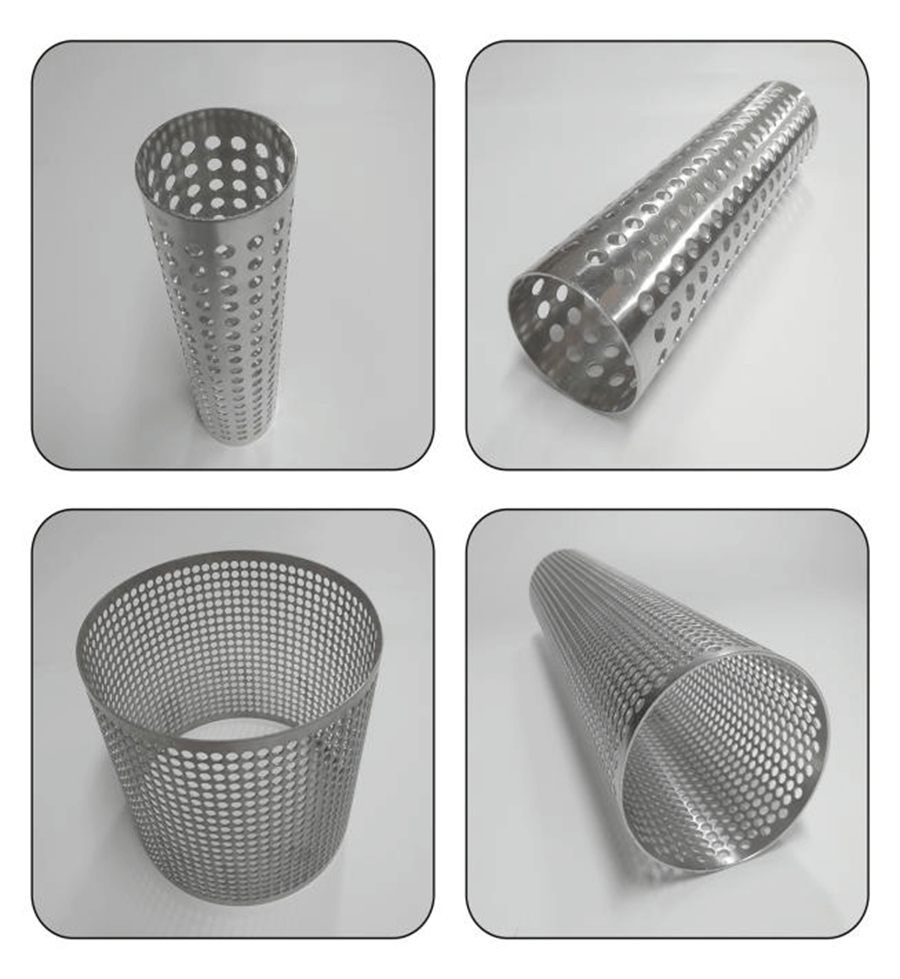

Filtration and Separation: Perforated steel tubing is commonly used as filters in various industries. The evenly spaced holes allow fluids, gases, or even light to pass through while capturing solid particles, contaminants, or debris. This makes it ideal for applications where separation or filtration is essential.

Acoustic Control: In architectural and industrial settings, perforated steel tubing can be employed to manage sound. The perforations absorb and dissipate sound waves, reducing noise levels. This is useful for creating quieter environments or controlling reverberations in spaces.

Heat Dissipation: Perforated tubing aids in heat dissipation. It can be used in applications where heat needs to be vented away from equipment or systems. The holes allow air to flow, promoting cooling and preventing overheating.

Structural Integrity: Perforated steel tubing can provide structural support while maintaining a reduced weight compared to solid steel pipes. This balance between strength and weight makes it suitable for applications where structural integrity is important but minimizing weight is a consideration.

Aesthetic Design: In architecture and design, perforated steel tubing offers a visually appealing option. The patterns created by the perforations can be customized to create intricate designs, adding a unique aesthetic to buildings, facades, railings, and other structures.

Customization: Perforated steel tubing is highly customizable. Manufacturers can create tubing with specific hole sizes, patterns, and open areas to meet the exact requirements of a project. This adaptability ensures that the tubing aligns with the intended function.

Ventilation and Airflow: The perforations in the tubing facilitate airflow and ventilation. This can be advantageous in applications where proper air circulation is needed, such as HVAC systems, industrial equipment, and automotive components.

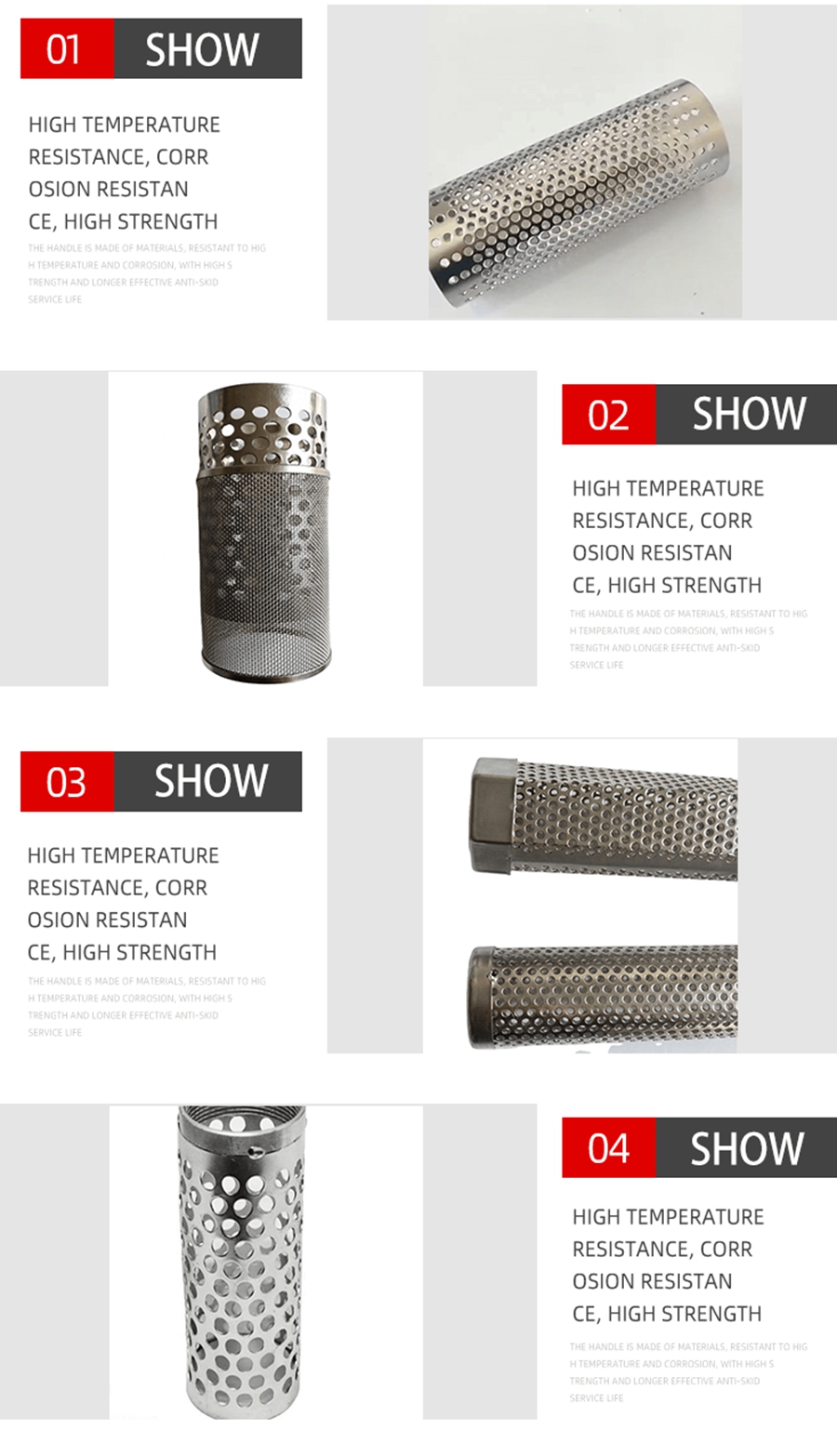

Corrosion Resistance: By selecting the appropriate type of steel and coatings, perforated tubing can exhibit good corrosion resistance. This makes it suitable for outdoor applications or environments with exposure to moisture and harsh elements.

Cost-Effectiveness: Perforated steel tubing can offer cost advantages over solid steel pipes due to the reduced material usage while still providing comparable strength and functionality.

Diverse Applications: The versatility of perforated steel tubing allows it to be used across a wide range of industries and applications, from industrial filtration systems to architectural design elements.

Filtration Systems: Perforated steel tubing is extensively used in filtration applications across industries. It's employed as filters in pipelines for liquids and gases, allowing the passage of fluids while capturing solid particles and contaminants. Examples include water treatment plants, oil and gas industries, and automotive air intake systems.

Architectural Design: Perforated steel tubing adds an artistic touch to architectural designs. It's used in building facades, decorative panels, and railings, creating visually appealing patterns and enhancing the aesthetics of structures.

Acoustic Panels: In sound-sensitive environments, perforated steel tubing is used to create acoustic panels that absorb and dissipate sound waves. This finds use in auditoriums, theaters, recording studios, and commercial spaces to control reverberations and reduce noise levels.

Heat Exchangers: Perforated tubing is employed in heat exchangers to facilitate the exchange of thermal energy between fluids. The perforations enhance airflow, aiding in efficient heat transfer and dissipation.

Automotive Components: Perforated steel tubing is used in the automotive industry for applications such as exhaust systems. The perforations assist in noise reduction and improve exhaust gas flow, contributing to engine performance.

Ventilation Systems: In HVAC (Heating, Ventilation, and Air Conditioning) systems, perforated tubing helps with proper airflow and ventilation. It's utilized in ducts and air distribution systems to ensure effective air circulation.

Oil and Gas Exploration: Perforated steel tubing is used in oil and gas wells to control fluid flow. It prevents sand and debris from entering the wellbore while allowing oil and gas to flow through the holes.

Industrial Equipment: Perforated tubing is integrated into various industrial equipment designs. It's used for sieving, screening, and separating materials in manufacturing processes.

Structural Support: In construction, perforated steel tubing can serve as structural elements. It's employed in frameworks for lightweight structures such as canopies, walkways, and shade structures.

Interior Design: Perforated tubing finds its way into interior design as well. It's used for room dividers, decorative partitions, and unique lighting fixtures, creating intricate patterns and enhancing the ambiance of spaces.

Agricultural and Farming Equipment: Perforated tubing is used in agricultural equipment such as seeders and planters. It assists in the controlled release of seeds and fertilizers during planting.

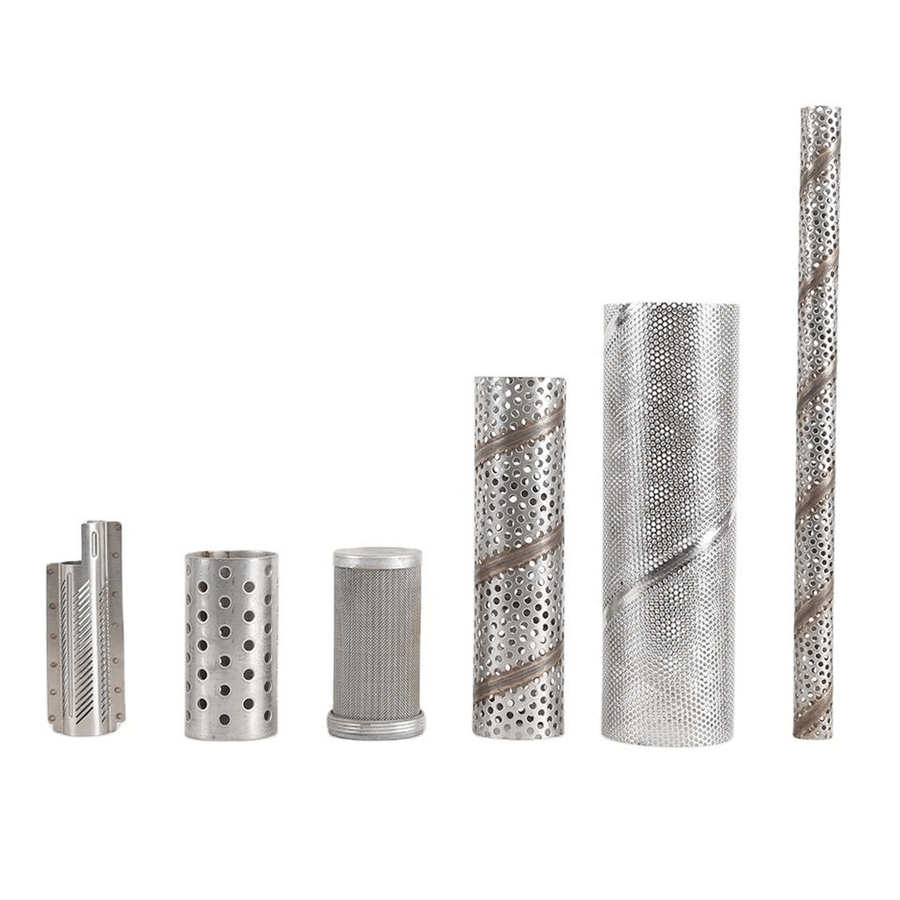

| Item | Perforated Filter Tubes/Perforated Pipes/Perforated Filter/Spiral Perforated Tube |

| Material | Carbon Steel,304/316L Stainless Steel, Aluminum,Galvanized, PVC coated |

| Hole Shape | Round, Slot, Oblong,Rectangular,Square, Triangle, Diamond, Hexagonal,etc |

| Hole Size | 0.1-50mm |

| Thickness | 0.1-6mm |

| Length | Customized |

| Outside Diameter | Customized |

| Opening Rate | 45%,60%,85% etc customized |

| Surface Treatment | Electric galvanized, Hot dipped galvanized, oxidation treatment etc |

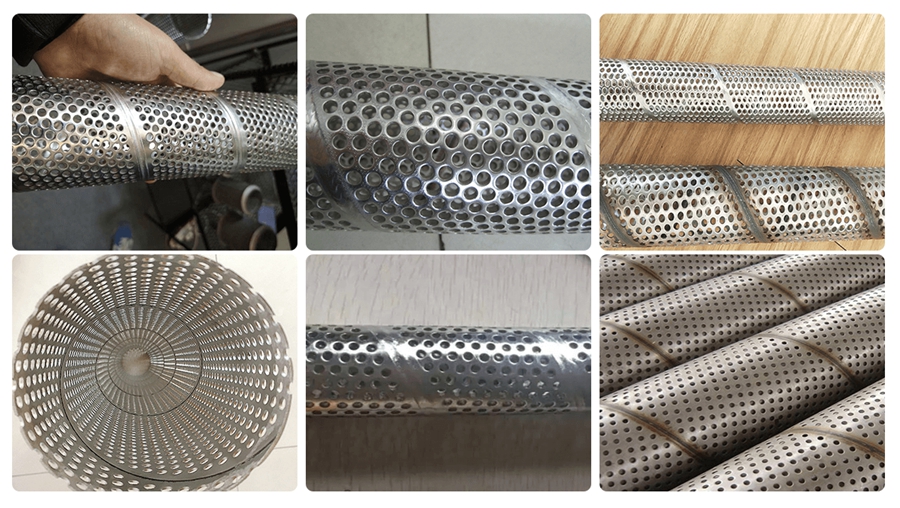

Perforated Tubes/Pipes In Straight Welding Pattern

Perforated Tubes/Pipes In Spiral Welding Pattern

Perforated Tubes/Pipes Features

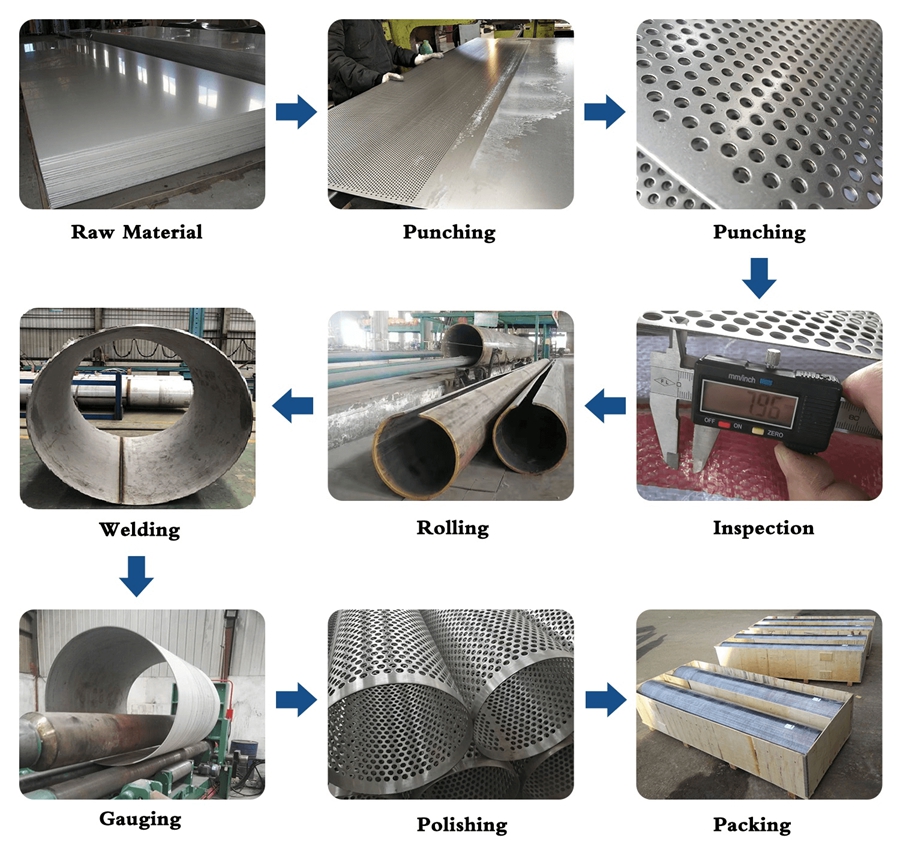

Perforated Tubes/Pipes Production Process

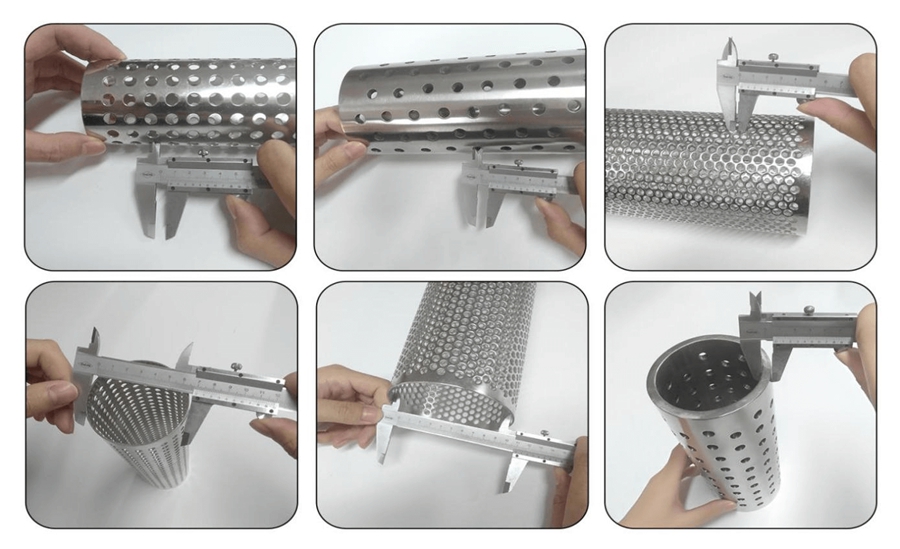

Perforated Tubes/Pipes Inspection

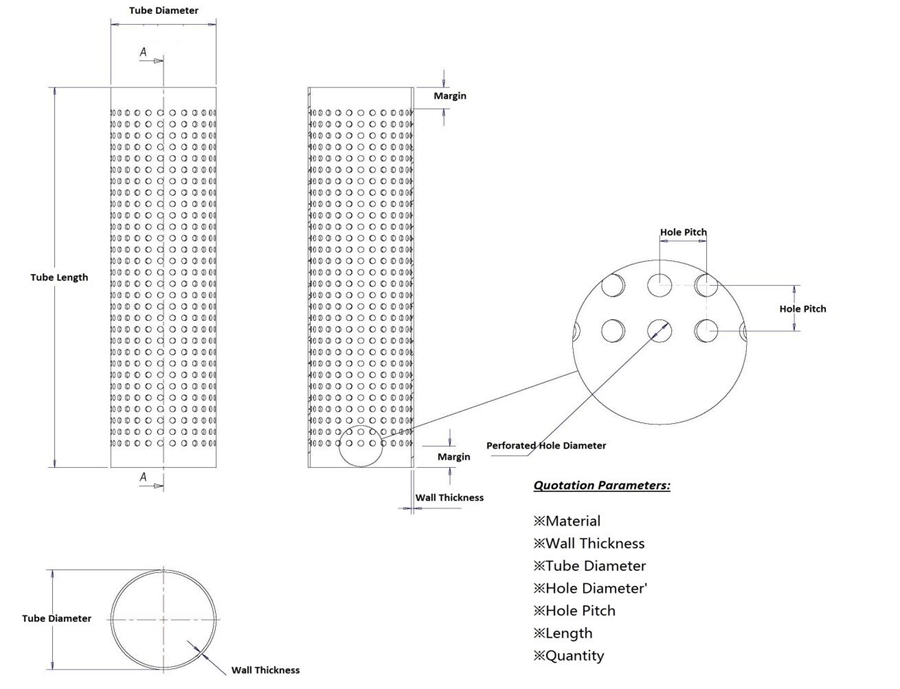

Perforated Tubes/Pipes Quotation Parameters

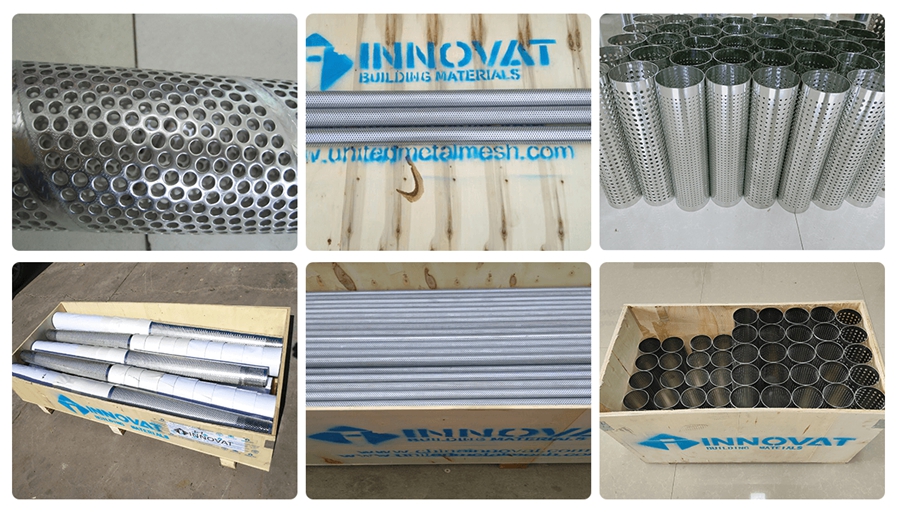

Several Projects for reference

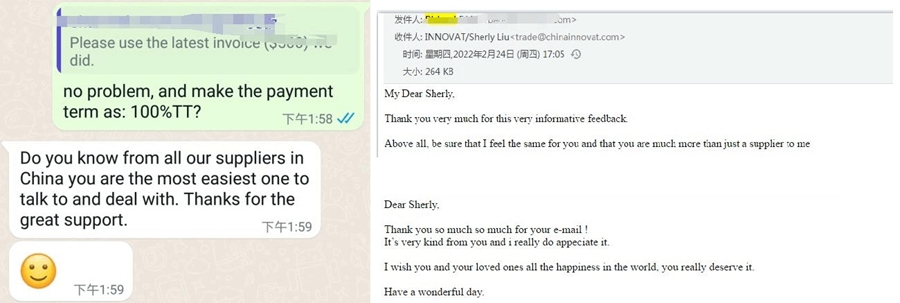

Customers' Feedback

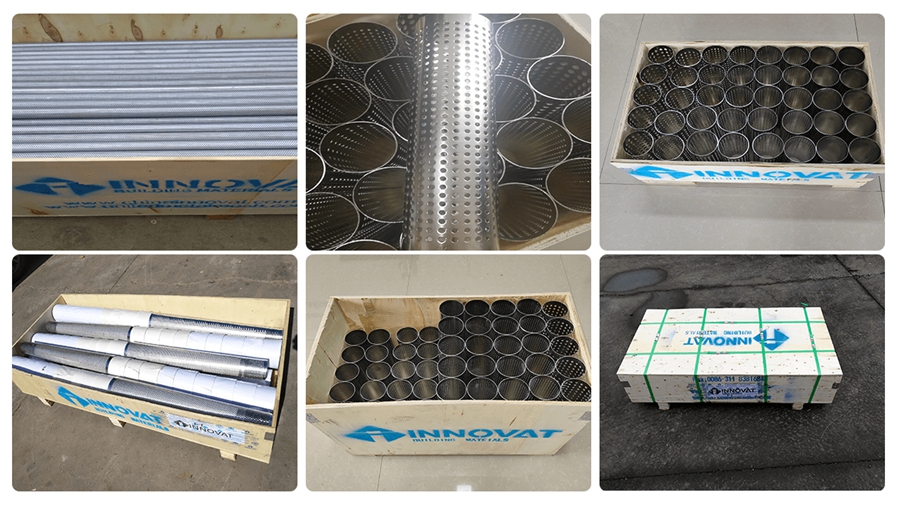

Package and Shipment

Tags: